Vacuum Gauge

While vacuum gauge can measure pressures accurately by being installed inside measuring object.The measurement accuracy could deteriorate depending on contamination source, resulting in measurement errors. And that could have negative effects on proper judgement and control.

Contamination sources are substances generated from measurement object and gases generated from sensors and wiring for control and measurement. These substances and gases adhere to vacuum gauge, and that could lead to the accuracy deterioration.

In vapor deposition process of plastic surfaces, evaporation of plastic plasticizer etc. could be a contamination source. Wiring, motor and sealant etc. inside vacuum equipment can generate organic pollution gases, these are the contamination source as well. And also, in semiconductor manufacturing equipment, adhering of organic metal source gases and remaining resist are the cause of contamination.

These contaminations cause critical issues. Regarding grid contamination, increase of emission current is to cause desensitization, emission stop and broken filament.

In addition, regarding collector contamination, it is often misunderstood that the vacuum has improved, but in fact there are cases in which contamination has decreased sensitivity. The problem is that it is not actually fail-safe.

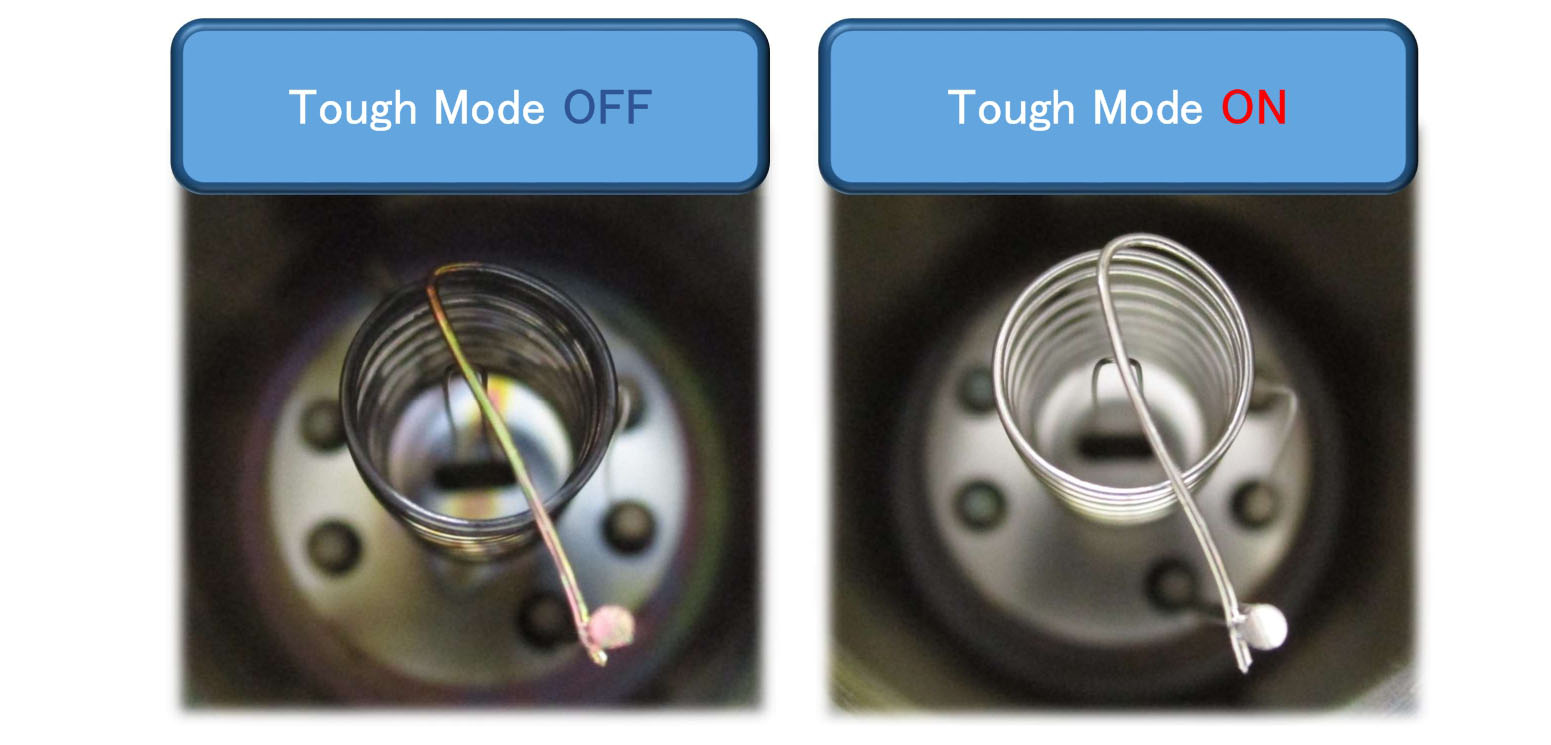

Our Vacuum Gauge “Tough Gauge” series reduces electrode contamination which causes problems, by using “Tough Mode” that measures while heating grid and collector.

【Grid contamination comparison.(Evaporative pump oil exposure test)】

*If you need TG Viewer, TG Dispaly Viewer and CAD data, please contact us using the contact information below.

Combination Gauge Tough Gauge

Combination Gauge Tough Gauge is a combination Vacuum Gauge of BA ionization gauge and pirani gauge. It can measure a wide range from atmospheric pressure to ultra-high vacuum while switching automatically. Thermometer is built in pirani gauge to correct temperature, and that leads to the reduction of errors due to temperature fluctuation.

Also, pirani gauge is made of corrosion-resistant material, and in high vacuum, BA ionization gauge operates with “tough mode” while heating grid and collector. Therefore, even in contaminated environment, it can measure accurately for a long duration without deterioration of accuracy.

- Combination Gauge Tough Gauge

- Model TG301CD

- Type Transmitter type

(with LED indication) - Measuring Range 1×10-8 Pa~1.2×105 Pa

- Connecting Flange NW25、ICF70

Cold Cathode Tough Gauge (CCTG)

Cold Cathode Tough Gauge (CCTG) achieved the prevention of electrode contamination and stable discharge in ultra-high vacuum, by heating cathode electrode. And also, the ceramic cathode gave this gauge unprecedented corrosion resistance. CCTG can measure halogen gas pressure, which was previously impossible.

- Cold Cathode Tough Gauge (CCTG)

- Model CCTG200C

- Type Transmitter type

(with LED indicator) - Measuring Range 1×10-8 Pa ~ 0.1 Pa

- Connecting Flange NW25、ICF70

- Cold Cathode Tough Gauge (CCTG)

- Model CCTG110S

- Type Separate type

(with LED indicator) - Measuring Range 1×10-8 Pa ~ 0.1 Pa

- Connecting Flange NW25、ICF70

Use

Vacuum deposition equipment, Etching equipment, Sputtering equipment, Electronic microscope, Ion implanter, Mass spectrometer, LPCVD equipment, Organic EL material refining, Accelerator etc.